THE DIAMOND

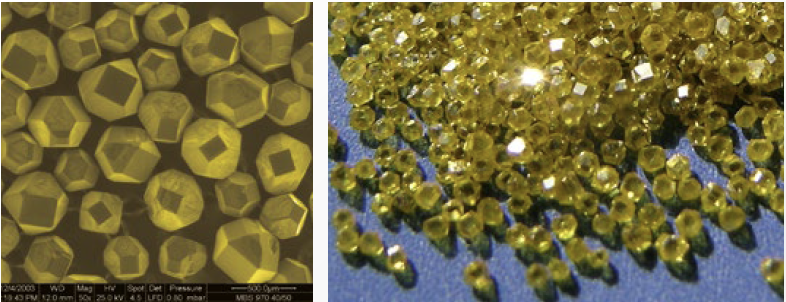

There are two types of diamond in existence, naturally mined and synthetic industrial diamonds. Synthetic industrial diamonds are generally stronger and their characteristics are more consistent than natural diamonds making them more suited to sawing, cutting and grinding. During cutting the diamonds are exposed to tremendous stresses. Diamond crystals with blocky shapes and smooth faces (cubo-octahedon) with good cutting edges that have a low breakdown rate or wear rate are required to ensure proper cutting speed and life.

This morphology gives the crystal additional strength and allows it to cope with the colossal stresses during its working life. Working applications range from the hardest granites, refractories and heavily reinforced concrete to soft marbles, limestones and other general building materials. This broad spectrum facilitates the use of a large variety of diamond grits.

Diamond grit is graded in a controlled process for its different characteristics. Diamond grit needs to crack and break off from the cutting edge in a controlled manner after it has become blunt, to allow a new piece of sharp diamond grit to begin cutting. If this does not happen, the blade will become blunt. If this process happens too soon then the blade will wear too quickly.

THE MATRIX OR BOND

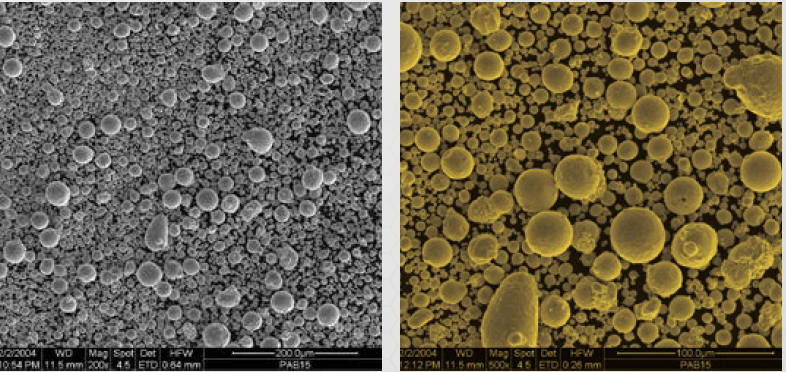

Holding the diamond in place is the fundamental factor that contributes to the performance of the product. The bond is a result of creating a strong holding matrix designed with a varying degree of hardness and abrasion resistance. Various metals with different hardness and characteristics are used, such as, Copper, Cobalt, Aluminium, Tungsten, Iron, Manganese, Bronze and other rare earth metals. Varying micron sizes and grades of these rare earth metals in a powder form are bonded together with the diamond to form the segment, depending on the application, (this is called Powder Technology).

The varying strength of the bond depends upon the chosen application, holds each diamond in place within the cutting segment, and this provides the cutting or grinding section of the product. As the cutting commences, calculated erosion of the bond takes place exposing the diamond. This is critical to the overall performance of the cutting or grinding action. As the bond wears in a controlled manner, the support for each diamond crystal is removed and the worn or blunt diamond breaks out, which in turn exposes a new diamond crystal to continue the cutting action. This should happen in conjunction with the original diamond becoming blunt. This wear characteristic of the bond should determine the speed of cut and product life.

The abrasive nature of the product being cut determines the hardness of the bond. For instance a product intended to cut hard engineering brick will have more Bronze in the bond, since the application is not abrasive and the bond will need to be soft enough to wear and expose the diamonds. On the other hand a segment cutting asphalt would have more Tungsten within its bond because it will have to withstand premature wear rates attributable to the abrasive nature of the aggregates within the asphalt.

If a blade is used on the wrong application, either the product will wear too quickly or “glaze over” which means there is no diamond exposure, so the product will not cut. (In general terms, hard but less abrasive aggregates and sand require softer bonds. Softer but more abrasive aggregates and sand require harder bonds). See Fault diagnosis at the back of this brochure for a diagram on “Blade not cutting”.

The main focus of any tradesman is how to get the job done in the safest, most economical way.

There are many costs involved in the sawing, drilling and grinding of concrete and asphalt. Cost of the worker, the machinery and of the course the tool itself that performs the work at the cutting edge. Each is significant in its own right however these can be significantly reduced by the use of great performing products in terms of life and speed.

Bad inefficiency in any aspect of tools usage manifests itself in poor unsatisfactory performance. More often than not poor performance from the tool is because of poor or wrong blade choice or technique by the operator.

MAXIMIZING EFFICIENCY = COST REDUCTION

When using a diamond tool, reducing the cost per inch-foot of material cut or holes drilled is the main goal. Cost per inch-foot is the most accurate indicator of blade efficiency.

This can also be calculated by dividing the depth of the cut in inches, by the length of the cut in feet. You will then take a number and divide it into the cost of the blade.

Example:

If a blade costs $250 and cuts 4″ deep for 1500 feet, the cost per inch-foot would be: 4″ x 1500’ = 6000 inch-feet. $250 / 6000 = $0.042 per inch-foot.

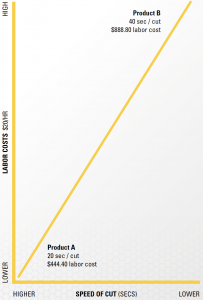

However that is not the only calculation to determine cost and efficiency as the labor rate is an absolute critical calculation to consider when trying to reduce costs on site which always gets overlooked.

Example:

Product A cuts concrete kerbs in 20 seconds and life of the blade is 4000 cuts.

Product B Cuts concrete kerbs in 40 seconds and life of the blade is 4000 cuts.

Workers rate per hour $20.00.

Product A takes 80,000 secs / 60/60 =22.22 hrs of cutting x $20.00 = $444.40 in labor + the cost of the tool

Product B takes 160,000 secs /60/60 = 44.44 hrs of cutting x $20.00 = $888.88 in labor + the cost of the tool

Product A is much more economical than tool B and saves $444.40 in costs and the operator also banks 20 hrs of extra time to complete other tasks on site.

Costs are also affected by blade efficiency, so life allied with cutting speed are crucial factors to consider in comparing diamond products on the market.

• Formulas to consider are inch feet achieved

• Cuts made

• Speed of the tool in use which is extremely important

• Segment height of the product allied with the cost of labor.

Copyright 2022 H2® Diamond Tools