The cutting segments of the blades, cores or grinding heads are put through a grinding process before they leave the factory to remove a layer of the metal bond so as to expose the diamonds. The tool will be ready for use as soon as it reaches site. Three major factors determine the blade or core bit performance.

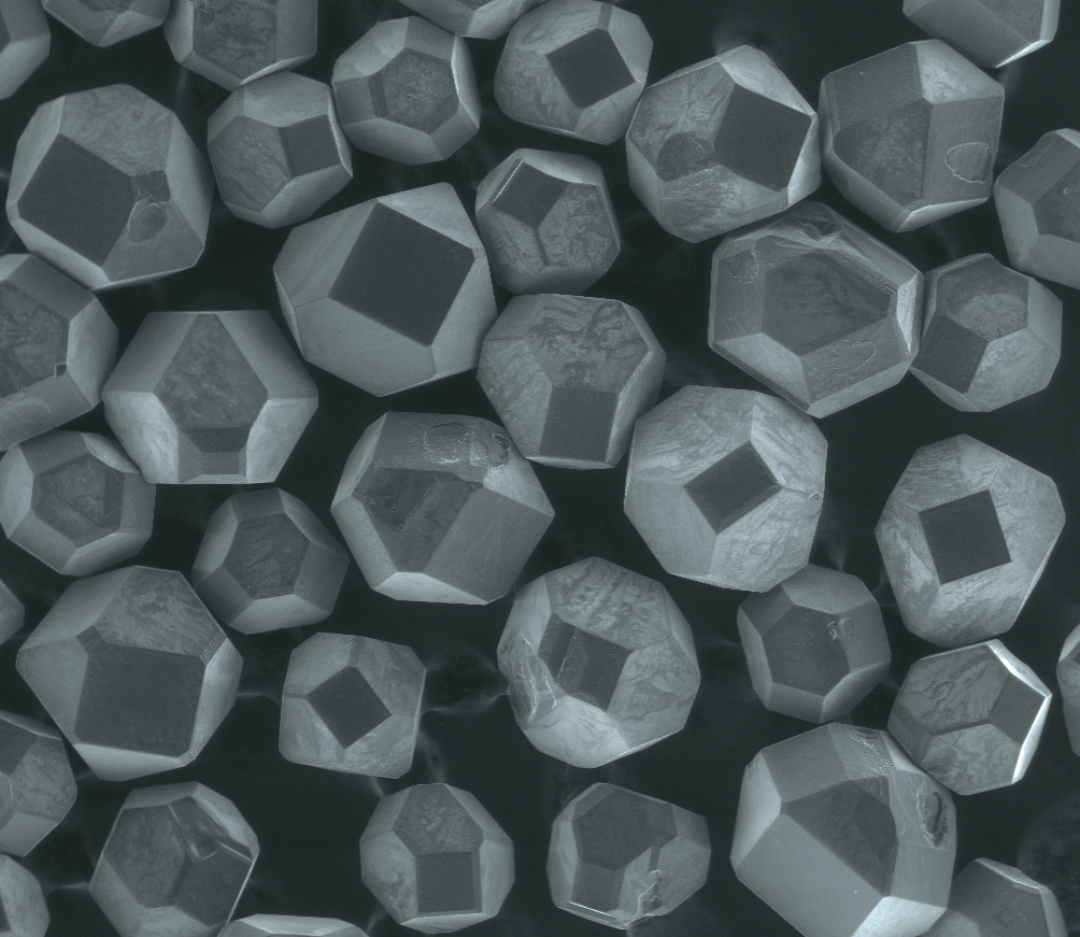

• The type and size of the diamond crystals

• The diamond concentration

• The hardness and characteristics of the metal bond.

In general terms, it is true that larger diamond crystals are better suited to softer aggregate types, while smaller diamond crystals will perform better on harder aggregates. Diamond concentration refers to the amount and dispersion of the diamond grit contained in the segment. Generally, the higher the concentration of diamonds and the closer the grit is spaced, the harder the segment. Highly concentrated diamond segments cut more effectively than lower concentrated segments.

However this again depends on the quality, size and shape of the diamond crystals. The bond or matrix is designed to wear away at a rate that is in proportion to the blunting, the breaking off or pulling out of the diamond crystal. These phenomena are designed to occur at exactly the right time, yet are different for each application and every structure and molecular composition. We have developed a unique array of bonding formulas that give unbeatable performance per unit cost over a period of time and will continue to develop different compositions to maintain its position at the forefront of the diamond industry.

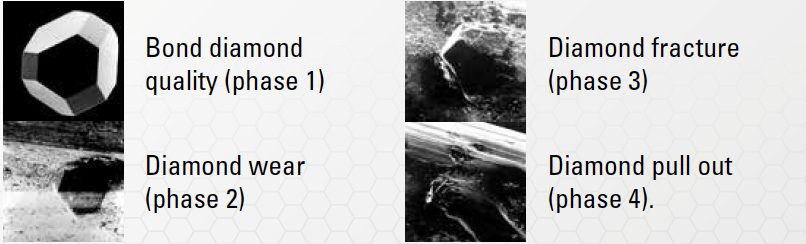

Generally the rate of wear of a given diamond segment is determined by the erosion of;

This wear process should correspond in unison with the aggregates abrasive properties.

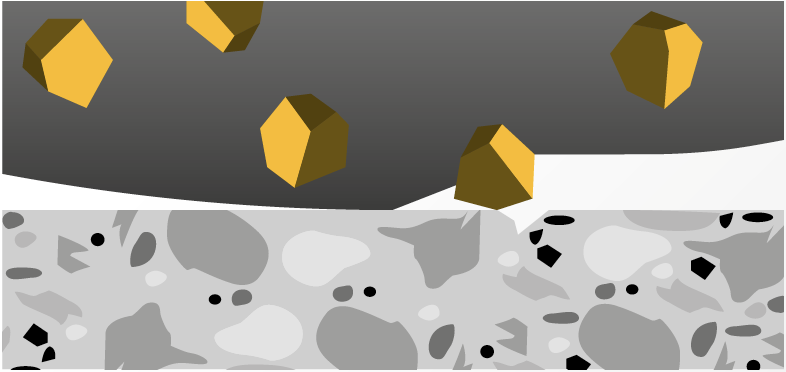

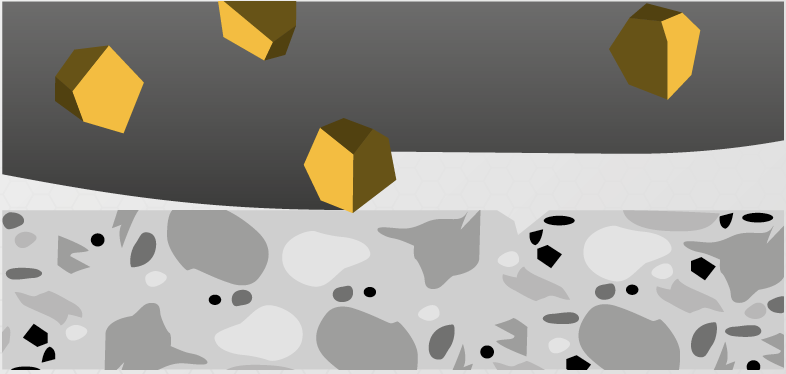

1. The actual grinding work is done by exposed diamond crystals that are held in place by the metal matrix or bond. Each diamond is supported by a bond tail which trails behind the diamond. While the blade rotates through the material, the exposed diamonds on the surface grind the material.

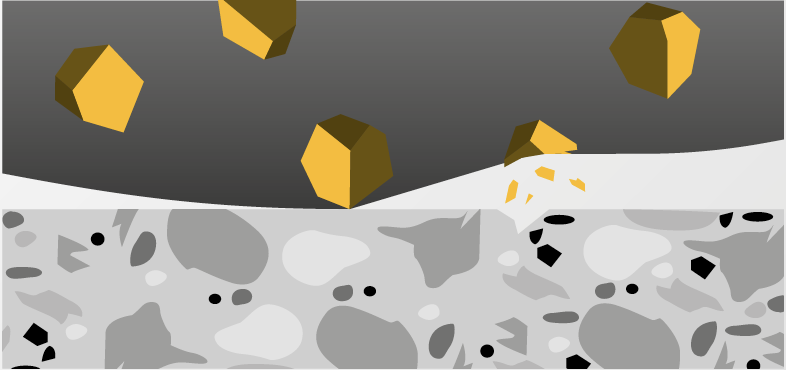

2. The exposed diamonds begin to crack and fracture after passing through the material hundreds of thousand times. Simultaneously the bond starts to wear away.

3. Eventually the diamonds fracture completely and are swept away with the material being ground. When wet grinding, this material, together with the water, forms a slurry.

4. Once a diamond has been pulled out, the bond continues to wear away and exposes a further diamond. This cycle repeats itself until the segment is worn to the core.

Copyright 2022 H2® Diamond Tools