TYPES OF SAWING

Types of materials and hardness

The hardness of a mineral is one of the most diagnostic and easy tests to perform in the attempt to identify an unknown mineral. Hardness is a measure of a mineral’s resistance to abrasion and reflects the atomic structure of a mineral. A mineral of any given hardness will scratch a mineral of a lower number. With a systematic approach, you can use minerals of known hardness to determine the relative hardness of any other mineral.

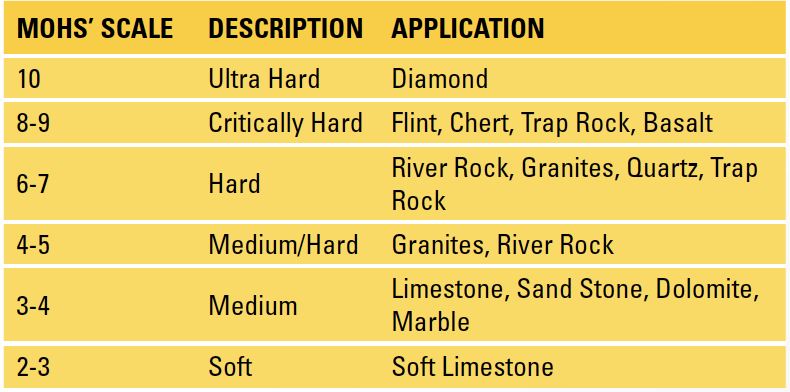

Aggregate hardness (Mohs Scale)

Effect

Harder aggregates require softer bonds. Softer aggregates require harder bonds. Harder aggregates make the blade cut slower. Softer aggregates make the blade cut quicker.

AGGREGATE SIZE

The larger the aggregates size the slower and harder the blade will cut. Different aggregate types within the application such as asphalt over concrete will subject the blade to different wear rates and characteristics. On these types of applications a mixed grit and grade is used to make the blade wear at the correct rate that will be conducive to normal blade life.

CONCRETE CUTTING

It is critical to assess the age of the concrete when trying to ascertain the correct blade type.

Stage 1: Approximately 10 hours after the concrete pour, the concrete is considered green. This is the best time to cut a concrete slab to prevent cracking from expansion after it has cured. At this stage the concrete has not cured or set and the sands and granules have not properly set into the binder or cement. When sawing in this type of application the slurry or debris rolls around in the cut above the segment area. This starts to wear the core. By using a deep draft segment we are able to eliminate this abrasive action as it throws out the new slurry that is made with each revolution of the blade. Dependant on atmospheric condition, the best time to cut green concrete is as soon as one can step on the slab without leaving an imprint in the concrete.

Stage 2: When the concrete is approximately 24 hours old it is more set or cured. The sand is more tightly held in the mortar making the concrete less abrasive during cutting. A slightly softer bond is required but some abrasion can take place.

Stage 3: After 24 – 72 hours the concrete is semi-cured. The sand is quite tightly held in the mortar thus reducing the abrasive properties of the concrete. A softer bond than on either stage 1 or 2 is required.

Stage 4: After 72 hours the concrete is considered cured. The abrasive sands are tightly held in the mortar making the concrete less abrasive to cut. When cutting the density and amount of steel should also be taken into consideration as well as the type of aggregate. As with all other cutting operations a certain amount of experience is needed as aggregate size, hardness and the amount of steel in the cut together with the atmospheric conditions and weather will add a variance to the correct usage and cutting properties of the application.

(Generally, as with other sawing, drilling and grinding operations, harder aggregates require softer bonds, softer aggregates require harder bonds. More dense materials require softer bonds, less dense materials require harder bonds. More steel in the cut requires softer bonds, less steel requires harder bonds).

ASPHALT

Asphalt does not age or cure in the same way as concrete. After the asphalt has been laid, the sand begins to set in the binder. However the sand is never held firmly so the abrasive properties of asphalt are quite high. When mixed with water, the abrasive slurry acts like a grinding paste and is extremely abrasive.

Core protection in the form of protective under cut segments are essential. Important factors to take into consideration when sawing asphalt are:

• The harder the aggregate, the blade cuts slower

• The softer the aggregate, the blade wears more

• Large aggregates will make the blade cut harder and slower

• The more sand binder in the asphalt, the faster the blade will cut and wear quicker.

• If the surface of the asphalt is very porous and broken, the more dirt and sand will fill the cracks, making the action more abrasive.

When laid, asphalt is sometimes not of the same depth throughout the cutting area. If the blade is used to cut all of the way through into the sub-base, the blade will wear prematurely, as this area usually contains abrasive sands and debris. Therefore, it’s important to check the depth of the asphalt and where the sub-base starts.

ASPHALT OVER CONCRETE

Asphalt over concrete creates a special assortment of conditions. The asphalt being very abrasive with small aggregates requires a hard bond that is fairly wear resistant, while the concrete beneath is cured, which requires a softer bond. The deeper the layer of asphalt means a harder bond is needed. The deeper the concrete section is, will mean that a softer bond is needed. On this type of application a mixed grit diamond of differing size and shape is used.

Copyright 2022 H2® Diamond Tools